A side table

← Back to Kevin's homepagePublished: 2019 November 8

Design brief

- conceal cable modem / wifi router

- use up leftover ¾" OSB from building my CNC enclosure

- height suitable for holding sofa drinks

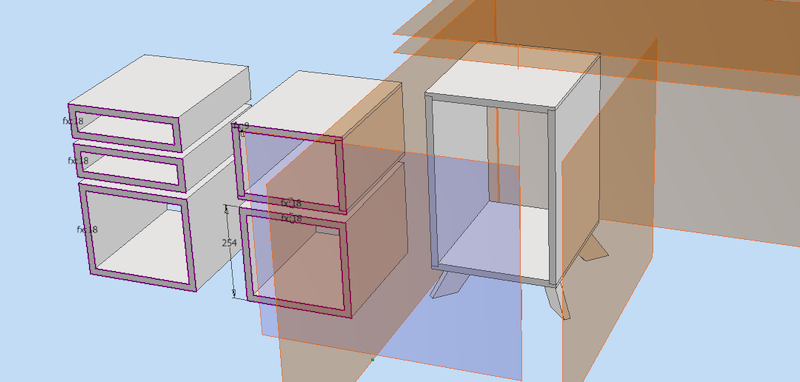

I sketched out a few designs on paper and then in CAD:

Construction

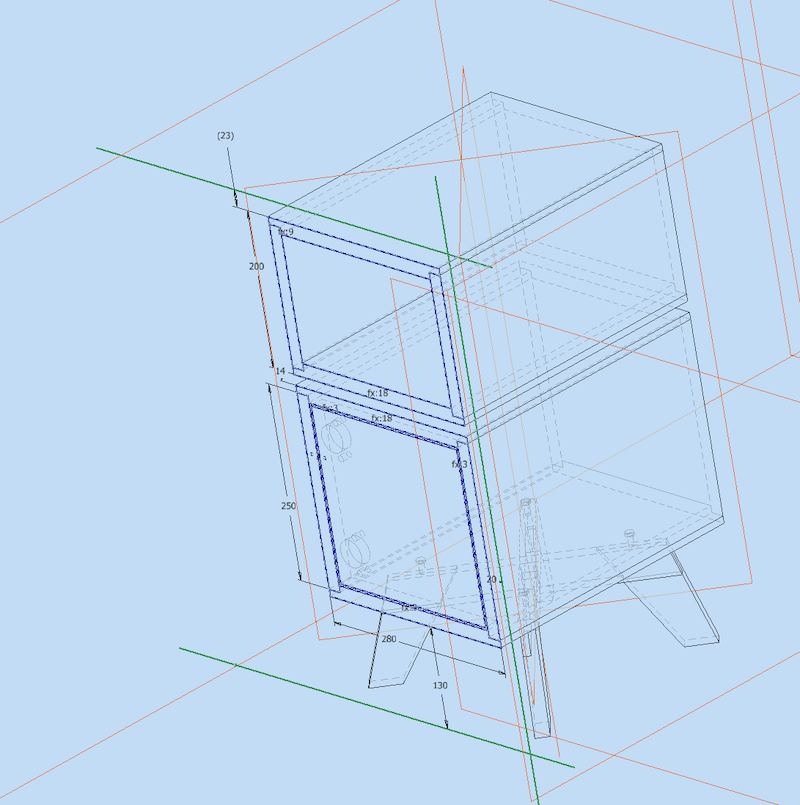

Both cabinet boxes are made from ¾" OSB glued together with rabbet joints.

There’s a small wooden spacer between the boxes to give the “floating” affect, with the cabinets attached via brad nails from the top of the bottom box through the spacer up through the bottom of the top box.

The legs consist of two horizontal members connected via halved joint, each of which has two feet attached via lap joint. Given the small size and simple geometry, the two feet and cross piece could’ve been cut from a single piece of stock, but I decided to get fancy just for practice when I eventually get around to making something out of solid hardwood.

The leg horizontal members were drilled to receive threaded inserts, into which M6 button head socket cap screws fasten them to the base of the bottom cabinet.

The door is soft close via 110 degree Blum Blumotion inset hinges. I choose the dowel mount hoping that it’d be removable (so I can change out the door with something neater later), but it’s a press-fit that’s probably impossible to remove — next time I’ll try the Blum “Inserta” hardware.

I don’t have a table saw, so I cut everything roughly by hand (in my backyard) and then cut to exact size on my desktop CNC machine, which I also used to machine the rabbets, screw holes, and door cups.

The OSB was finished with 4 coats of Varathane gloss water-based polyurethane, which made the piece turn out much nicer than I’d hoped for. I mean, it’s OSB, so I had low expectations, but turns out that a glossy finish can make anything feel fancy…

I sanded with 100 grit to roughly smooth out the OSB, brushed on the initial coat with a $1 foam brush, let dry for a few hours, then sanded again to flatten out the grain raised by the water-based finish. Then I applied 3 more coats, waiting about 2 hours between coats for them to dry.

My understanding is that this water-based stuff sprays very well, so next time I’ll probably try a $50 Amazon-special HVLP sprayer, which should be faster than a foam brush.

All-in-all, I was plesantly surprised with how well this turned out. Which is good, because I have probably 40 sqft of OSB left to use up…