Building stools

← Back to Kevin's homepagePublished: 2017 August 1Overview

My girlfriend Nicki and I decided to try and use up all of the miscellaneous wood scraps in her basement by building stools. I ended up making four over the month of July.

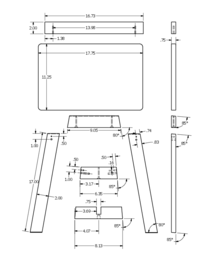

NORRÅKER clone

As a warm up, I decided to copy an Ikea stool that we already owned, the $35 NORRÅKER:

Like the Ikea original, each longitudinal side consists of three glued together pieces, joined to the opposite side with shorter cross pieces using dowels and screws. (I used SPAX construction screws, since I didn’t find any fancy copper-colored screws in the basement.)

The wood was some softwood I found near the laundry machines in the basement. It had weird scorch marks on it, so I painted it with “Burnt Clay” and “Saga Blue”, both leftover $5 Behr (Home Depot) latex paint color samples.

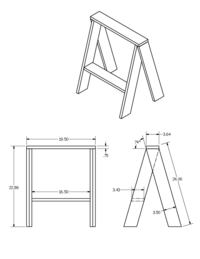

AA Stool

Nicki found this design by Torafu Architects. I just eyeballed the photos and drew up my own plans:

They’re made out of Ikea “Sultan Lade” bed slats and assembled with more SPAX construction screws. They’re a little wobbly side-to-side, likely because the wood is only ¾" thick and the design has no lateral bracing.

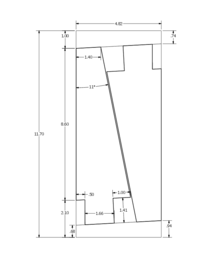

LSL Endgrain footstool

I got the idea for this stool from the Minimalist Maker on YouTube, who did a 2x4 endgrain stool. Mine is basically the same idea, except I used leftover laminated strand lumber from the LSL cabinet:

The top consists of LSL cubes glued together, and the legs are single pieces that are joined as tenons. I used Titebond II for the glue, and finished with a few coats of Polycrylic. Pretty sure this stool is indestructible.

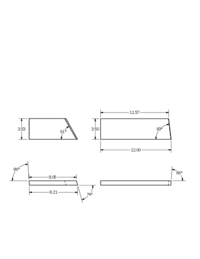

Sansa Stool

I found the Sansa Stool by Makoto Koizumi on Pinterest, and ended up making two variations:

All of the pieces are made out of the previously mentioned Ikea bed slats, and held together with pocket screws. (I used the Kreig R3 jig, which was awesome.)

The design was actually quite tricky, because the three pieces come together at a compound angle to create a little depression for the seat. I couldn’t figure out how to express in Inventor the appropriate constraints, nor could I come up with an analytic solution, so I manually changed the angles until things seemed to fit together.

Assembly was also difficult, because I couldn’t really clamp the pieces together when pocket-screwing them together. If I needed to make more of these (and wanted them to actually be nice), I’d probably try to make a positive jig of the seat, so I can clamp the individual leg pieces flush against that before screwing them together.

Plans

I drew rough plans for all of the stools using Autodesk Inventor. The dimensions are in decimal inches, so they’re incomprehensible regardless of your background.

If you take a crack at any of the stools, send me a photo!

Party!

We also invited our friends to make stools over the month of July, and they did not disappoint. Here’s a photo of all the furniture that showed up: