Workshop pricing notes

← Back to workshop series indexPublished: 2016 August 1Last updated: 2016 August 24This page has rough numbers I’m using for material pricing calculations.

Since I’m determined to use the full extent of the site location, these rough calculations won’t affect the size of the structure. Rather, they’ll inform the following questions:

Building structure: stick built vs. timber post+beam vs. steel

Building envelope: what’s the marginal cost of insulation / airtightness? (See also: workshop airtightness requirements)

For whatever reason, people in building world just hate putting pricing numbers online, so I got all of the numbers below by calling various suppliers and talkin’ with sales reps. (Except Home Depot, they have a great website and their lumber is pretty solid too — at least here in the Pacific Northwest.)

Shared costs: $40–45k

All building types will share the following costs:

Excavation / Prep: A few rotted out trees need to be removed (so they don’t fall on my workshop) and some dirt needs to get pushed around. This will cost about $1k and a six-pack (my neighbor has a bulldozer).

Electricity: I need to bring power to the site, which requires trenching from my neighbor’s transformer (about 700’ feet away) and laying down 2" PVC conduit. The conduit install will cost about $2k ($500 for conduit, rest for trackhoe rental and labor). The power company installs the conductor, and charges $4,400 for first 100’, then $3/ft for the rest. So about $9k total.

Foundation: I got two ballpark quotes for a 30’ × 30’ monolithic slab foundation: A 4" concrete slab with 1’ wide footings around the perimeter that go down 18" (at my location, the frost line is at the surface). Ballpark quotes were: $8k and $10k. Maybe I throw down foam to insulate the slab (see BSC’s Slab Happy article), which will cost me about $1k.

Permitting: My county charges permit fees based on building valuation. Assuming 1000 sqft, a pole building permit (valuation at $16.60/sqft) would cost $99.76; a garage permit (valuation at $33.25/sqft) would cost $753.69. Who knows what happens if I park my car inside a pole building, so lets just round up and say permits will cost $1k.

Geotechnical engineering: An engineer digs some holes and gives me a report with estimated bearing capacity and other exciting soil facts. I got two quotes for this: $3k and $8k. In the first case, the engineer prefers oversizing foundations to extensive investigation, in the second the engineer wants to dig lots of pits. I’m going with the former. (My residence will likely require this too, so at least the cost would be amortized.)

Siding: I’m keen on using metal siding with some wood accents (more on this later). 22 gauge AEP Mini-V siding costs $3/sqft; $0.07 per color-matched fastener; $350 freight for 2000 sqft of panel. Say $8k for 2000 sqft of metal siding; $2k for reclaimed wood (maybe cheaper, since I may be able to purchase from neighbors w/ dilapidated barns).

I’m big on roof overhangs too, so lets say there’s 300 sqft of soffit visible from below. If hipster tongue and groove wood paneling costs $10/sqft, that’s another $3k.

Roofing: This isn’t visible from current massing, and so could be the cheapest effective system. Say it’s the same as the metal siding: $3k for 1000 sqft.

TBD: windows, doors, flashing and trim details

Stick-built structure: $25–30k

Stick-building is the typical residential construction system in the United States. Think 2x4 or 2x6 stud walls with plywood wall and roof/floor diaphragms for lateral strength.

My structural assembly for walls and roof would have (from inside to outside) 2’ OC stud spacing, ½" plywood sheathing, WRB, 2" continuous rigid rockwool insulation, then siding.

Here’s my best estimate for that cost (see stick built details below):

| $5k | R8 wall, 2000 sqft (4 walls × 30’ long × 15’ high) |

| $7k | 2x12 LSL studs (alt: 2x12 studs $2k) |

| $2k | crew or crane rental for raising tall walls |

| $6k | R12 roof, 1000 sqft |

| $5k | 20 RedBuilt trusses (2’ O.C.), 30’ span |

Total: $25k

Beyond the price, my primary concern with sticks is that the walls would be heavy and I’d need to get a small crew together or rent a crane to raise them.

I could try building them in place, but I have no experience whatsoever doing that. Plus 2x12 LSL (actual: 1 ¾" × 11 7/8") weighs 6.5 lbs/ft, so even a single 15’ stud weighs about 100 lbs and would be tricky to handle alone.

Post + beam: ???

An alternative to stick-built is a post + beam construction method. I have no idea how difficult it would be to engineer this, so this option is TBD on me finding a structural engineer to have beers with.

That said, any materials savings over the stick-built would likely be offset by engineering costs and the difficulty of handling larger timber members (requiring, e.g., cranes).

Steel structure: $10–15k

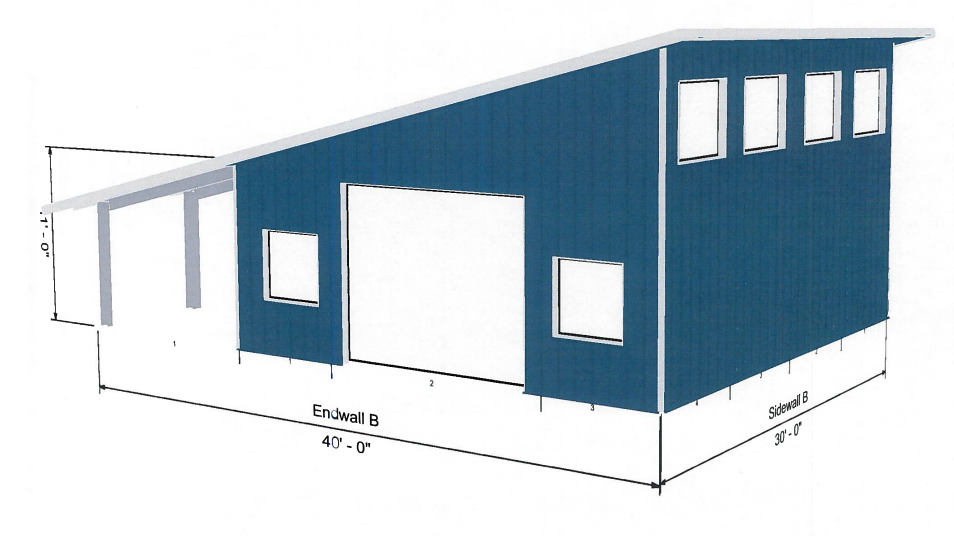

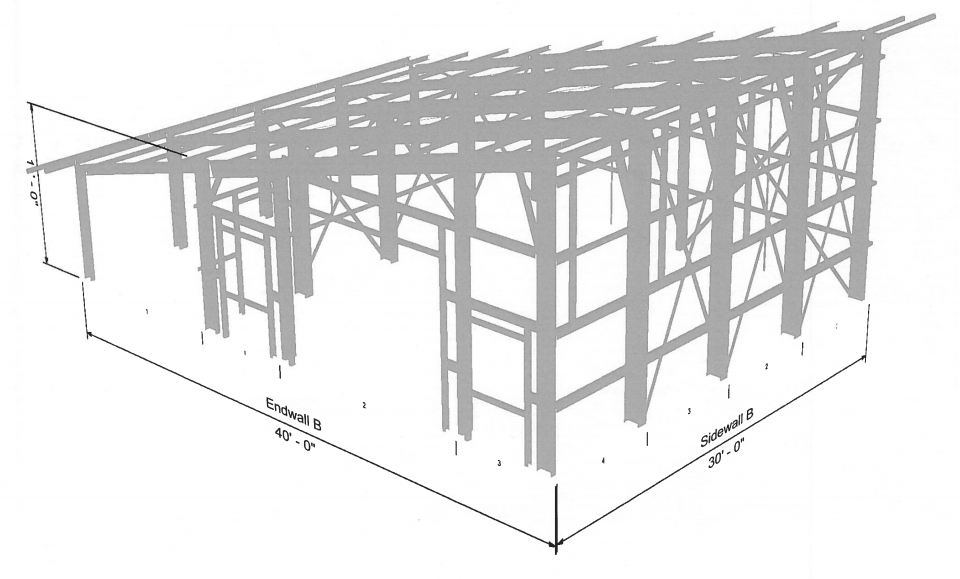

I wasn’t sure what to expect when I requested a ballpark quote for a 30’ × 30’ steel building with attached carport. I talked with one vendor on Monday afternoon and received a detailed quote on Tuesday morning for the following structure:

Turns out that lots of people want barns, so someone wrote a computer program that takes a building footprint with snow/wind loads and spits out a steel frame.

The total price was $15k, which included roof, siding, trim, R19 roof insulation, R13 wall insulation, stamped engineering documents for the structure and foundation, and delivery.

This is a third to half the cost of sticks, and would also be much easier for me to assemble by myself or with a small crew.

Given this cost difference and ease of assembly, it’s very likely that I’ll go with a steel frame for my structure.

That said, I want a rad-looking workshop — not the cheapest possible tractor storage — so the trick with this is going to be figuring out the material and assembly aesthetic details.

Appendix: Stick-built details

Material costs

- ½" CDX plywood: $0.50/sqft

- 2x4: $0.30/ft

- 2x6: $0.54/ft

- 2x12: $1.50/ft

- 11 7/8" LSL: $5.50/ft

- 2x6 Timberstrand LSL: $3.27/ft

- 1 ¾" x 5 ½" LP LSL: $3.14/ft

- 2x8 LSL: $4.00/ft

- ComfortBoard R4/inch: $0.75/(inch sqft)

- DeltaVent SA WRB: $1.50/sqft

- Vycor enV-S: $0.75/sqft

- CCW 705 WRB: $0.50/sqft

- Tyvek HomeWrap: $0.12/sqft

- ¾" Rough sawn cedar: $0.85/sqft

- 3" roxul cavityrock: $1.20/sqft https://www.insulation4us.com/roxul-mineral-wool-cavityrock-24-x-48-x-3.html

Roof assembly

Dead loads:

- ½" plywood 2 psf

- 20 ga corrugated roofing 2 psf

- misc. dead load ~ 6 psf

Each truss has tributary area (ignoring end trusses, which have less load) of 30’ span × 4’ OC spacing = 120 sqft.

This gives 1200 lbs dead load per truss.

Cowlitz Snow load @ 1000’ elevation is 55 psf. Windswept mountain, unheated building, partial exposure gives roof snow load of 37 psf, or 4500 lbs per truss

40" Red-L parallel chord truss spanning 30’ has uniform load of 205 lbs/ft → 6,000 lbs total load per truss.

This should be sufficient for 120 lbs dead load + 4500 lbs roof snow load.

Alternatively, could just do trusses 2’ OC and definitely good to go.

RedBuilt trusses about $6–8/ft. This is the same ballpark as 16" TJI’s ($7.17/ft for 360s), and I’d prefer trusses for the interior utility.

Purlins: 30’ long * (30’ / 2’ OC spacing) = 450’ of 2x4 @ $0.30/ft ~ $200

R12 roof assembly = $6/sqft = WRB $0.50, plywood sheathing $0.50, 3" rockwool insulation $2.25, purlins $0.25, fasteners $0.50, roof panel $2

Wall assembly

R8 wall assembly = $6/sqft = WRB $0.50, plywood sheathing $0.50, 2" rockwool $1.50, siding $3, fasteners $0.50

24" OC framing: (15 studs per wall × 15’ + 60’ of plates) × 4 walls → ~ 1,200’ lumber

2x12 (* 1.50 1200) ~ $2,000

LSL (* 5.50 1200) ~ $7,000