Hi friends,

My millifluidic PCR work is progressing:

though I’ve spent the last two months shaving several quite-interesting yaks.

The first has been MSLA (resin) 3D printing; understanding constructable geometry, developing a progress for washing parts, debugging z-axis tolerances, etc. I’ve been shocked by the quality of parts coming off my $500 printer from $40/kg resin; everything is coming in within 0.1mm, which is more than enough for my needs. Note the 0.2mm high embossed labels on the four sections of the millifluidic test card above (USB-C connector at right for scale).

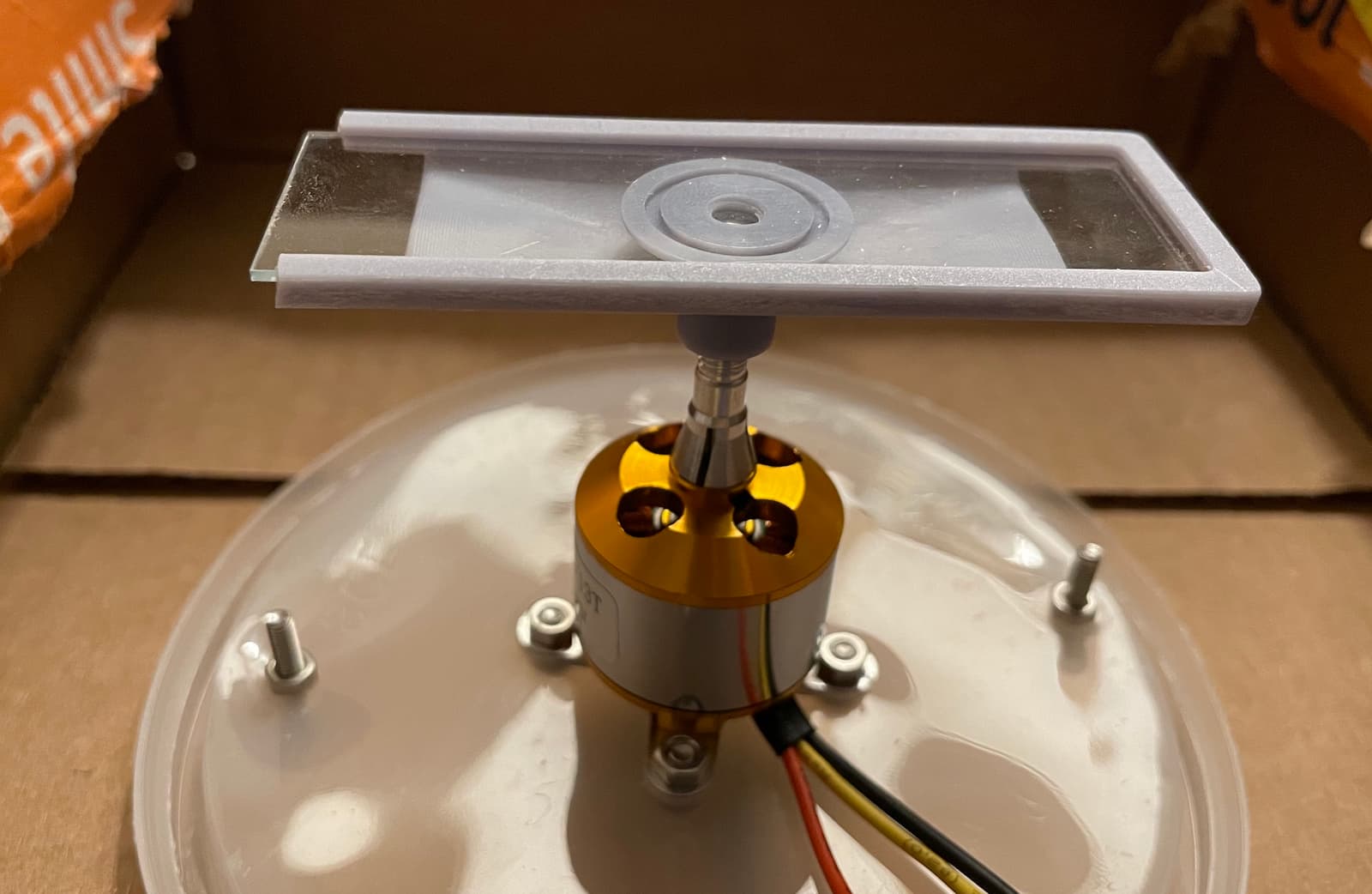

Most of this 3D printing ramp-up took place while shaving the second yak; building a spin-coater:

which I’ve needed for coating glass microscope slides with thin layers of adhesive (to cover open-faced millifluidic channels, themselves 3D printed as above, or perhaps fabricated on PCBs).

So far I’m happy with the $35, terrifyingly fast-spinning contraption shown above. See my design notes for the gory details on various false-starts (vacuum hold-down) and overview of 3d printing process/settings.

The third (most-exciting and ongoing) yak shave has been developing a programming language / compiler. Usually this is either dreadfully boring (“a mixed functional / object-oriented language that compiles to JavaScript”) or a nerd’s cry for help indicating one is about to disappear for a few years before almost certainly returning empty-handed (perhaps with a conference talk or podcast interview consolation prize).

However, rest assured that my language:

- Is already being bootstrapped (controlling the spin-coater and a few works-in-progress)

- Has been described, unprompted, by all of the so-called who’ve seen it as “not a real language”. Presumably because it lacks features like “control flow”, but that’s needless gate-keeping: A “language” is just custom syntax/semantics and a “compiler” is just a program that translates those into another language which can be run on a machine, and I have both. Chew on that!

Designing languages has never been an interest of mine. This one is borne entirely from my experiences over the past year working on embedded systems, in particular reasoning about hardware and physical-reality-driven constraints like:

- mapping hardware peripheral signals out to available pins

- choosing clock signal mappings/prescalers necessary to generate signals with specific frequencies or duty cycles

- selecting hardware peripherals based on DMA bus availability

I’ve previously discussed my frustrations with solving such problems by fighting Rust’s types and within spreadsheets.

The microcontroller search / pin assignment website from July was a first stab, and the language is a more powerful tool that fits neatly into my existing text-editor and version-control workflows.

At some point I’ll write up details for the language / programming nerds, and eventually put together an online REPL / tutorials a la Sketch.systems, but for now I’m focused on feedback people who’re in a position actually use it in anger.

So, if you’re working on a bare-metal embedded project and want to solve a complex set of pinout / signal / peripheral constraints at compile-time and generate optimal register code, drop me a line! (Especially if you’re working with STM32 chips, though I’m open to extending to Atmel or NXP chips with a motivated collaborator who can test on hardware.)

Misc stuff.

Precision Japanese manufacturing set to electronic music: springs and vinyl records are my favorites; turn on subtitles for process description

“Some said an open-world experience this immersive wasn’t possible.”

“I wanted to do something unique for a proposal, so I designed and 3D printed a mirror array to ask the question for me.”

“The House of Faberge made 52 "Imperial” eggs as Easter gifts for Tsars Alexander III and Nicholas II to give to their wives and moms. 46 of these survive. I will rank all 46 Imperial Faberge eggs.“

"What are some compelling examples of new things we could do with energy abundance—say, 10x (or more) energy usage per capita?”

“Of course, Andreessen was correct to claim that software was eating the world, but he had the causation backwards. Software’s high valuations were not the result of its extraordinary technological promise. Rather, the software sector had become the primary locus of innovation because of its high valuations. Its financial characteristics allowed software to attract growth investment while other sectors no longer could.

"Shout it from the rooftops, as it were, that we as a nation did a thing, and a thing is a thing we can do, because One Man stood up and was heard. It’s big news. The people need to know.”

“Sketch-n-extrude mechanics is the work-horse of traditional CAD packages for a reason”

“CadQuery is for 3D CAD what jQuery is for JavaScript”

Putting a sonar depth sensor into a surfboard

“the balloon world cup was last week. watch this space”

“So, what is it about this illustration that’s so interesting? On the one hand, it’s just typical node-wire programming viewed through the Corporate Memphis lens. But on the other hand, there’s a bunch of made-up detail that is suggestive of a rich possibility space — much richer than all those established node-wire languages have actually explored.”

“I generally don’t consider myself justified in being offended by someone’s words or actions if I haven’t done at least an hour of research on the specific accusation in question. Unless there’s some specific reason that it’s worth it for me to spend that time, this means I usually don’t get mad at people by reading things. I haven’t identified any problems caused by this choice.”

A partially-automated medium-throughput homemade cider press with lasers

“The rough idea is to inject a high voltage pulse directly on the backside of the silicon of the target chip in order to generate faults.”

This Is How the Trillion-Dollar Coin Could End Debt Ceiling Fights for Good

Jamie Brandon On bad advice

“Lab-grown meat is supposed to be inevitable. The science tells a different story”

“ Workers had to be encouraged to use the new safety features of their machines, and not to circumvent them for convenience. Propaganda campaigns were launched, including cartoons featuring the misadventures of characters such as ‘Willie Everlearn’ and ‘Otto Nobetter.’”

“Q: I thought all God’s creatures were perfect? A: Humanity has waited long enough for God to do something about the left-handed.”

While I’m feeling savvy about using a 3d mouse in CAD, this YouTuber is sculpting dioramas in VR.

“A Bubble Tea–Making Robot Is a Portent of Things to Come”